Bulk Bags

Reliability in bulk.

Bag Features

Style

- 4-Panel – Large bag with 4-panels sewn together like a box.

- U-Panel – Large U-shaped bag with 2 side panels sewn to each of the opposite sides.

- Tubular – Circular design eliminates side seams, thus improved stability, sifting, and moisture resistance.

- Baffle – Typically a 4-Panel or U-Panel construction with internal fabric baffles to make the bag square.

- UN Certified – Designed to store and transport hazardous materials. ABC Polymer Bulk Bags are certified for Packing Groups II & III.

- Ventilated – Manufactured from woven polypropylene to allow airflow.

- BRC/AIB – FDA Food Grade: free of contaminants. ABC Polymer Bulk Bags BRC/AIB Certified.

Fabric

- Color Options – Yellow, green, white, black, blue, red (a minimum order quantity is required).

- Uncoated – Standard polypropylene fabric.

- Coated – Fabric that is laminated with polypropylene film.

- Conductive – Fabric that conducts electrostatic charges.

- Ventilated – Fabric that is breathable.

- Type C Groundable – Designed to control for electrostatic charges by grounding. The fabric is woven with interconnected conductive carbon tape and ground tabs.

- Type D Dissipative – Designed with static protective fabric that does not require grounding. Delivers safety levels equal to that of Type C without grounding.

- Non-woven Polypropylene – Fabric from bonded fibers.

- UV Stabilized – A feature of an FIBC fabric that provides protection from prolonged exposure to the sun’s degrading UV rays. An additive is added to the resin prior to extrusion of the yarns to provide this protection.

Liner

- Standard Loose Tube – Liner loosely inserted into the bag to fit any bottom or discharge spout.

- Form Fit – Liner fitted to the design of the bag to maximize container and liner capacity.

- Baffle – Liner added to baffles to stabilize the bag during filling.

- Groundable – Conductive polyethylene liner.

- Polyethylene Liner – Standard liner material used to control for moisture contamination (thickness ranges from 2-5 mm).

- Woven Polypropylene – Also known as a bag-n-bag, provides added strength and puncture resistance for heavy or sharp products.

- Non-woven Polypropylene – Liner allowing liquid to filter out.

- Sewn – Liner applied and sewn into the seams.

- Glued – Method of adhering the liner to the bag.

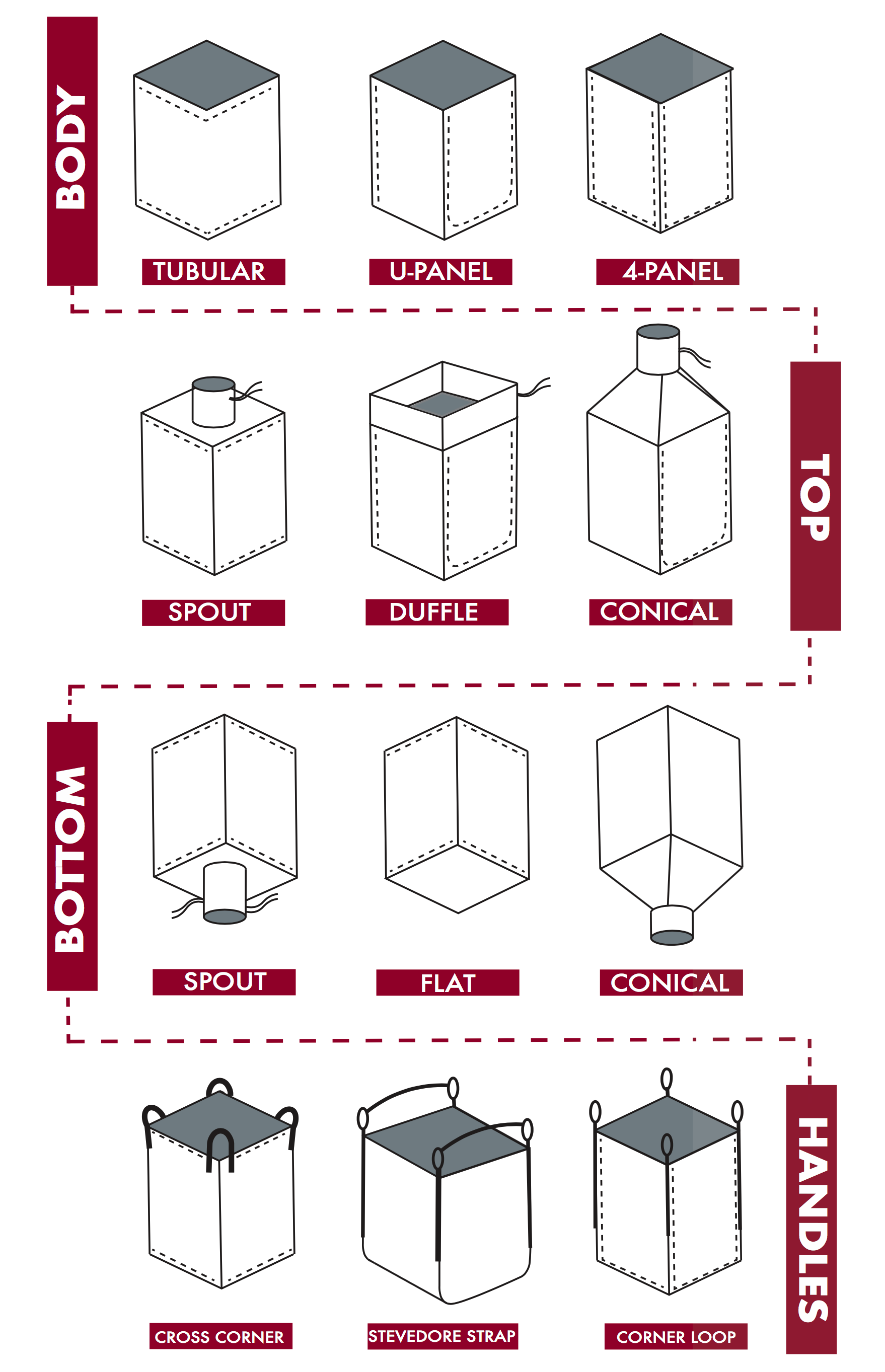

Top

- Open Top – Economical for in-plant use, but not optimal for packaging.

- Duffle Top – Top opens out of the bag for easy filling.

- Inlet Spout – Top wraps around the filling spout for easy filling and spill-free shipping.

- Conical Top – Allows for optimal filling space for products that need time to settle.

Bottom

- Flat Bottom – Standard polypropylene fabric bottom with no discharge capability.

- Discharge Spout – Allows the bag to discharge from bottom in a smaller capacity.

- Full Bottom Discharge – Allows for the entire content to be discharged in one motion.

- Conical Bottom – Designed to help discharge flow.

- Closures – Tie closure, Velcro closure, diaper closure, star closure, drawstring closure.

Lift Loops

- Side Seam – 4 loops sewn directly into the side seam.

- Corner – 4 loops sewn on the top of each corner for easy forklift access.

- Cross Corner – 4 loops sewn across corners for easy forklift access.

- Stevedore Straps – 4 loops sewn directly into the side seams with 2 straps connecting side loops for single point lifting.

- Single Loop – 1 large loop connecting two opposite sides for easy crane access.

- Sleeves – 2 sleeves sewn on opposite sides of the top for easy forklift access.

Seams

- Standard – Used for applications where sift-proofing is not required.

- Single Filler Cord – A single rope used to prevent product sifting.

- Double Filler Cord – A double rope used to prevent product sifting.

- Triple Filler Cord – A triple rope used to prevent product sifting.

Additional Safety Features

- Perimeter Belt or Band – Bias tape/strap sewn around the top seam as a reinforcement or identifying mark – also known as Safety Belt.

- Double Reinforced Loops – An additional layer of webbing sewn throughout the lift loops for abrasion protection.

- Lift Loop Wear Pads – An added layer of protection against wear and tear of lift loops.

- Fully Belted Bags – Lift loop webbing sewn down both sides and across the bottom panels of the bag.

Accessories

- Inlet Spout – Closure that covers the top spout to avoid leakage contamination.

- Sift Proof Seams – Seams that offer tight closure against products that are very small to guard against the product contents sifting out of the bag.

- Velcro Ties – Used for bags that need quick and frequent opening and closing capabilities.

- Document Pouch – Typically made of either polyethylene or polypropylene, it is where shipping or identifying documents are usually placed – also called a Pocket or Envelope.

Specialty Bags/Certifications

- UN/DOT Certified – UN and DOT Certified bags for transporting hazardous materials.

- AIB and BRC Certified Food Grade – Certifies the manufacturing facility meets requirements set by the American Institute of Baking and British Retail Consortium for food products.

- FDA Compliant Food Grade – Meets the standard requirements for bags with intent to transport food.

- ISO 22000:2005 Certified – Certifies the manufacturing facility adheres to a Food Safety Management System.

- ISO 9001:2008 Certified- Certifies the manufacturing facility adheres to a Quality Management System.